Purem by Eberspaecher Introduces Cathode Isolation Valve – RVBusiness – Breaking RV Industry News

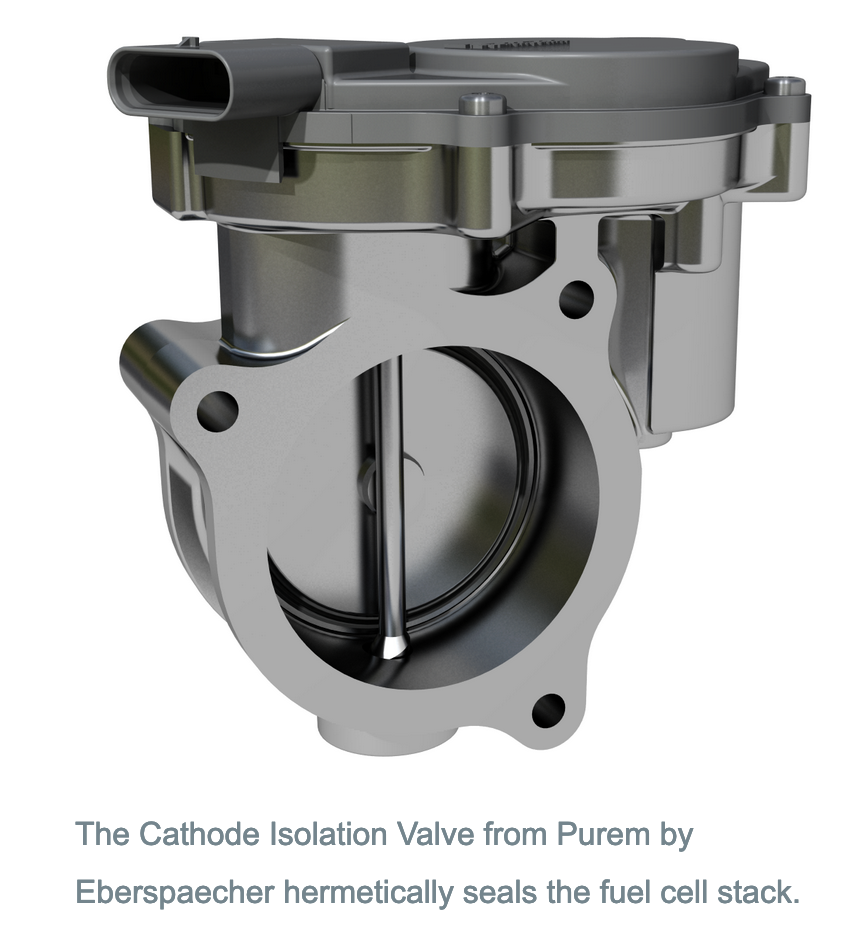

ESSLINGEN, Germany – Reliable sealing of the stack is a top priority for the safe operation of fuel cell systems. The new cathode isolation valve (CIV) from Purem by Eberspaecher meets the strict requirements for seal-tightness and prevents premature aging.

The use of hydrogen as an energy carrier plays a major role in the decarbonization of industry and mobility. Depending on the application, hydrogen-based fuel cell systems are a sustainable operating alternative, for example, for heavy duty commercial vehicles, passenger cars or stationary applications. The heart of a fuel cell is the so-called stack, in which the chemical energy of hydrogen is converted directly into electrical energy through an electrochemical reaction. Balance of Plant components guarantee safe functioning and efficient operation. The special requirements include sealing the cathode path to prevent leakage and therefore premature aging.

Longer service life

The Cathode Isolation Valve (CIV) from Purem by Eberspaecher is used in the cathode air path of the fuel cell system. The reliable sealing concept hermetically isolates the stack when the entire system is shut down, preventing premature stack wear and extending operating life. At the same time, the conditions inside the fuel cell remain constant, enabling faster restarts. A fail-safe function of the Cathode Isolation Valve guarantees that the fuel cell stack is closed quickly and reliably in the event of a fault within the system. The component is also adapted to the specific installation spaces of fuel cell systems: Their compact dimensions and customer-specific connections allow them to be designed for different applications.

Advanced material design

With its expertise in the field of materials science, Purem by Eberspaecher has designed the CIV for the specific requirements. The product is made of special materials that are insensitive to hydrogen. Another focus is on the use of suitable alloys that are resistant to attack by ultrapure water, which is a by-product of the chemical reaction and can lead to corrosion of metals.

Continuous control

The electric actuator of the CIV allows the cover position to be continuously adjusted in order to individually regulate the mass flow and pressure within the fuel cell stack and thereby optimize operation. This additional functionality ensures lower counterpressure and has been developed in cooperation with experienced partners. When developing Balance of Plant components, the exhaust and acoustics specialist draws on its Clean Mobility experience in exhaust technology and utilizes synergies from valve development. The Cathode Isolation Valve was tested in close cooperation with existing customers in order to further develop the first sample components for rapid series production.