Volta Power Systems Intros All-in-One Power Distribution Hub

VPS Power Distribution Hub 30

EDITOR’S NOTE: A Q&A with Volta Power Systems CTO and Co-Founder Jack Johnson follows this release.

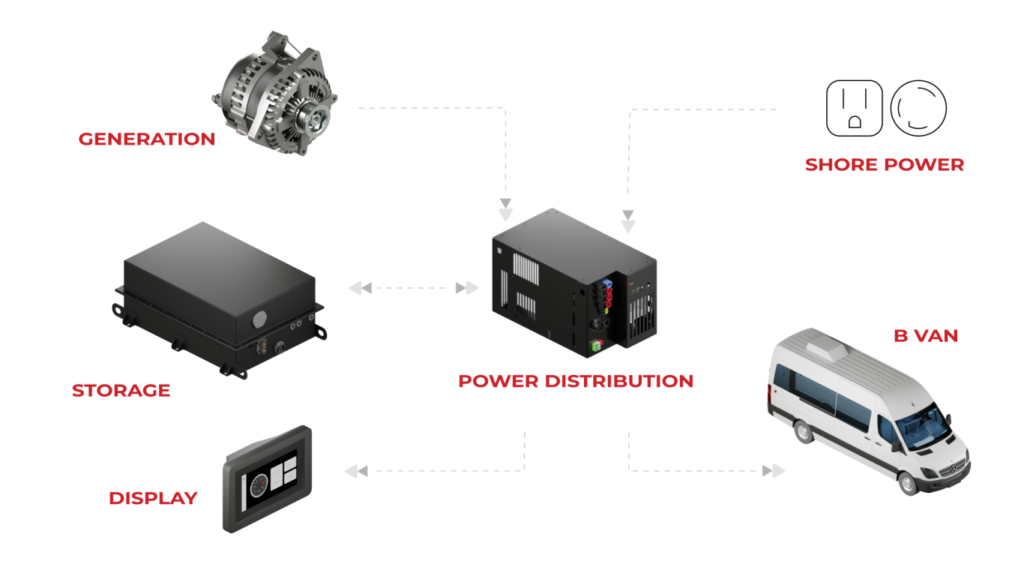

HOLLAND, Mich. – Volta Power Systems, a leading supplier of mobile li-ion power systems, has announced the release of its new Power Distribution Hub. Volta developed the all-in-one distribution unit to meet the needs of RV manufacturers in simplifying li-ion system integration.

The Power Distribution Hub contains all the necessary equipment and ports for charging, AC and DC outputs, and MPPT solar control while reducing the total footprint required for integration. So far, the company is offering a base unit for a 30-amp shore power experience and will launch a 50-amp version early in 2023.

Volta launched the integrated solution first with Airstream on the E1 Package for Interstate and Atlas touring coaches in the summer. Paired with Volta’s energy storage pack and under-the-hood generation, the Power Distribution Hubs will integrate either Volta’s 3200W or 8000W inverter/charger with configurable space for DC conversion and MPPT solar charging.

VPS “As a trusted partner in the leading Class B brands, including Winnebago, Storyteller Overland, Tiffin and Airstream, our end goal is to provide RVers and OEs with the simplest and best ‘green camping’ solution that seamlessly integrates into a vehicle. We want to make advanced energy accessible, effective and easy to use,” said Jack Johnson, CTO of Volta Power Systems. “This new product is a great example of collaborative efforts built upon trust. We are proud to continue developing new products that save our customers time during installation. The Power Distribution Hub provides the same emission-reduction and improved comfort with less wiring complexity and reduced labor costs.”

With the Power Distribution Hub launch, Volta is positioned for growth in key fleet and RV markets where clean, mobile power adds the most value, including Class As and towables. Along with the company’s NITRO system, which generates exportable power from tow vehicles, the new hub will reduce complexity and costs for integration in towable RVs, where industry margins have traditionally been tighter, preventing li-ion options.

“It’s all about maximizing accessibility to clean, high-performance technology,” Johnson said. “By enabling more RVs with automotive-grade energy storage, we’re enabling RVers to camp anywhere without compromising on noise or emissions.”

Jack Johnson

What follows is an edited Q&A between RVBusiness and Johnson.

RVBusiness: The whole idea here – and this isn’t meant to discount its high technology – but your new Power Distribution Hub is really all about making things a little easier. So, how does this make it easier for OEMs?

Johnson: Our company motto is making advanced energy simple for new markets. And that’s the challenge that any company has when they’re facing electrification. It is scary, it’s very expensive, and obviously there’s a lot of energy and a lot of power involved. When you do it wrong, you’re going to get in the news the wrong way. So, taking that step into advanced energy can be scary.

Traditionally, inverters, converters – all those other components – are wired into the vehicle by electricians on site. That’s not necessarily well standardized work. There’s lots of turnover. And these critical connections are as important as fuel lines on a car, and with more and more power running through those lines, it’s really important that they are properly put together.

Well, the way the RV world has to function – a low level of capital investment, but high dependence on labor – it’s very hard for them to be consistent with high quality from unit to unit just because of the nature of us being humans. We all make mistakes, we get fatigued.

So, what we’ve done is to help solve some of those problems. We are pre-assembling all of those components – your solar controller, the alternate engine control, all of the electronic control pieces, the inverter, all that fusing, all those connections that would be made in the vehicle.

By putting it all together, assembling it in the factory and then running it through a 100% testing system, we’re doing all that work for them right here. We’re reducing those risks dramatically, which in turn will save them labor on the line and reduce the complexity and education that their labor needs.

RVB: So, from an OEM production standpoint, this reduces the potential for costly installation mistakes?

Johnson: Today they (production line workers) are responsible for making all those connections. Most of them are going to be a bolted connection, and the worst conditions are putting crimps. Do you have a calibrated crimper? I find that the calibrated torque wrenches, calibrated tools, they just don’t exist in the RV market. They build a high variety of a lot of products, and they depend on skilled labor. But they don’t have work instructions; they don’t have all these details. They’re not automotive. They can’t put that type of overhead investment into building these units and then still make them affordable.

The challenge, though, is the risks and complexity associated with advanced energy. I mean, you’re basically turning these things into electric vehicles. They might not drive the drivetrain, but they drive the home. Well, that level of complexity is increasing dramatically, so therefore the risks are increasing. So, you can’t continue to do it that way any longer (current multi-component installations) or you’re going to have more issues. You’re going to be creating scenarios where you could create risk and safety hazards that really could hurt a company because they didn’t have the quality inspection process, quality control procedures, work instructions, training, that they need to do to ensure these systems work successfully.

So, we take the time, working with our customers, to put it all together and pre-assemble them. We put it through a process called a HIL – Hardware in the Loop – and it’s basically an automated testing protocol machine that validates every device within that system as well as all the power connections and communication lines. Traditionally, you can’t do that in the RV world. You test it by turning it on and hoping it works.

RVB: And the Power Distribution Hub is designed to fit most anywhere on an RV?

Johnson: Ideally, it’s going to fit in a cubby in a storage bay in a basement. It was designed to launch for Airstream, so it’s going up under the bed area in a corner, and it’s integrated within rounder cabinets. So, it’s tucked away, it’s hidden, but it’s got all the power distribution components in one place.

And then everything has quick connects on it. So they’re all positive lock quick connects. There’s no screw, there’s no tools, there’s no turning connectors, there’s no twerking. They’re going to connect, click. Do a pull test to make sure it’s connected.

RVB: And, of course, the Hub is designed to work within the Volta system itself, right?

Johnson: Yeah, definitely. The thing about the Volta system is to think about it this way: the battery packs we build is a fuel tank. So, this will be the engine, right? It’s all how the power is transmitted and what type of power is transmitted. Is it a 12-volt, 24-volt, 120-volt AC, 240-volt split phase, 50- or 60-hertz? And we’re taking in solar power. You have to convert all those energies to line up with the electrochemistry that’s in the battery. And all that function is happening in, what we call the Power Distribution Hub, or PDH.

RVB: Is the Power Distribution Hub designed to be used with any type of RV?

Johnson: We focused on two types, with the first designed for 30-amp applications.

So, when you think of about 30 amp, a lot of trailers are designed around 30-amp short cord plugin. Your B-vans, your smaller vehicles, usually are designed for that 30-amp RV service. What we focus on is, first, to make the user experience feel like you’re on a 30-amp short cord feed. So, when you’re unplugged from shore power, everything will work just like you’re plugged into shore power. That’s our goal. So that one should fit that segment.

And then we have a larger unit called the PDH 50. It will have a full-time 240-volt split phase inverter that, even if it has a single phase coming in, it will still create two phases going out. That will be the ability to replace a generator on the larger vehicles by always providing a true 240-volt source even when you are on a single leg at a campground.

RVB: You’ve mentioned the benefits for OEMs, how about for the RV owner?

Johnson: The biggest thing for me is I like to see the consumer’s usability. When I say ‘usability,’ I mean the ease of using the vehicle improves.

Think about it. I’ve seen statistics where the average RV is used 30 days a year. Well, if you’ve got this huge investment and you use it only 30 days a year – mainly because you can’t get the campground – or you know you’re going to need power or your food’s going to go bad. Or it’s so hot outside but you don’t want to run the generator all day. Or you want to go somewhere, but you need to be quiet, so you don’t want to start generator up and have everybody within five miles know where you’re at.

Well, this gives you the freedom to be all of that – stealthy, comfortable, go anywhere, have all the conveniences you want, not worry about a campground. So now you can use your RV 10 more days a year? Or 20 more days? How much money did I really save you on your dollar per use, right? I mean the value you create in really using the asset you purchased, the cost goes down dramatically because you can use it more.

RVB: We haven’t talked about cost, but it’s safe to assume this will not be an inexpensive proposition.

Johnson: Well, we are a premium brand, but the reality is, where can you find a fully U.S.-based engineering services company that will help you with design, development, execution, full system, wiring, harness control, warranty, liability support. We do their customer service. We have people on the phones. You need help, you get a call. And we’re a small business, like all of them. We know how hard it is to make all of this stuff work. And I don’t know anybody else that’s doing it at that level that we are.

But again, we’re focused on how we can make that OE successful. We’re not a mass consumer aftermarket sales company where most of our competitors are going to try to sell both to the aftermarket and the OE.

Our play is how do we help them integrate really good quality systems that are lowest risks, best performance, and best in class? And when we’re not best in class, we’re going to be there and you’re going to get support and you’re not going to have to carry dozens of very expensive engineers to maintain all this stuff. You have us to support you.

The big thing here is, again, we’re trying to innovate to help the OE be successful. And that’s our goal. If we can do that, and do that better every day, then we’re doing the right thing.

For more information on Volta Power Systems, please visit: https://voltapowersystems.com/

Source: https://rvbusiness.com/volta-power-systems-intros-all-in-one-power-distribution-hub/